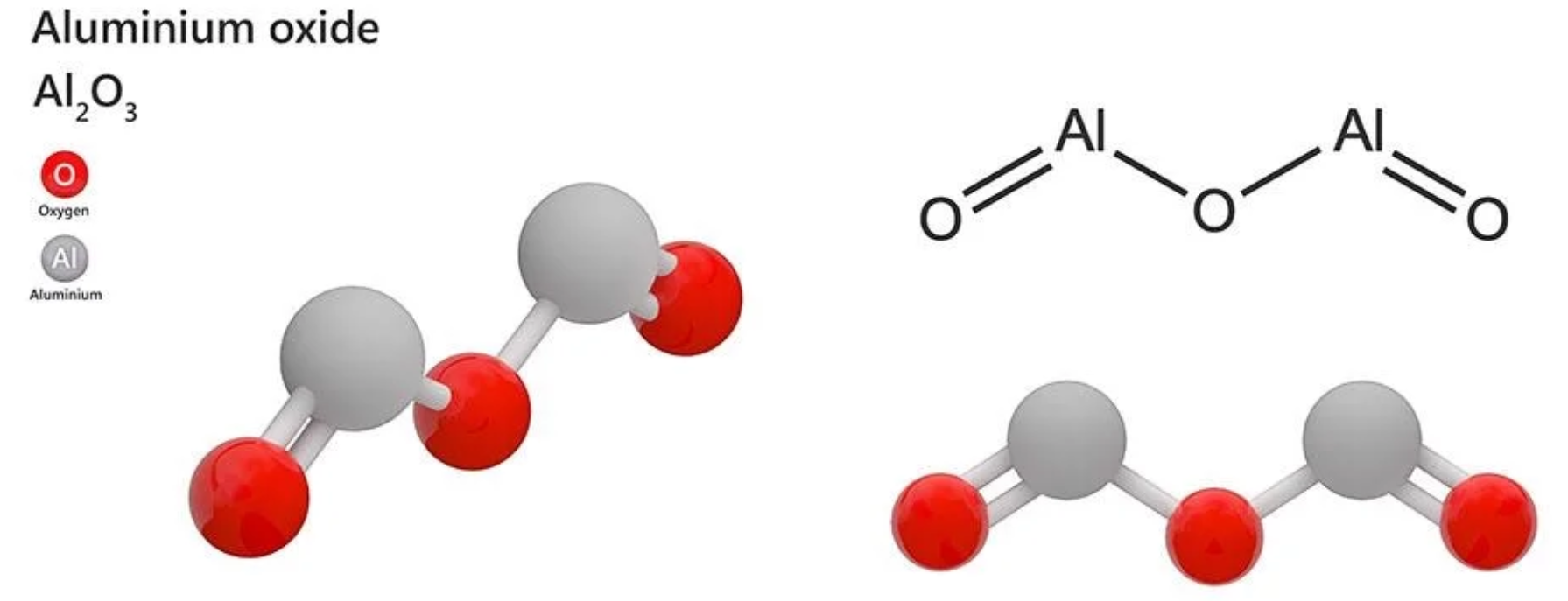

♦Alumina (Al)2O3)

Ibice bya ceramic bikozwe na ZhongHui Intelligent Manufacturing Group (ZHHIMG) bishobora gukorwa mu bikoresho fatizo bya ceramic bifite isuku nyinshi, 92 ~ 97% bya alumina, 99.5% bya alumina, > 99.9% bya alumina, na CIP cold isostatic pressing. Gutunganya ubushyuhe bwinshi no gutunganya neza, ingano ya ± 0.001mm, uburyohe bugera kuri Ra0.1, bikoresha ubushyuhe bugera kuri dogere 1600. Amabara atandukanye ya ceramic ashobora gukorwa hakurikijwe ibyo abakiriya bakeneye, nka: umukara, umweru, beige, umutuku wijimye, nibindi. Ibice bya ceramic bikozwe na sosiyete yacu birwanya ubushyuhe bwinshi, ingese, kwangirika no gushyushya, kandi bishobora gukoreshwa igihe kirekire mu bidukikije birimo ubushyuhe bwinshi, imvange n'umwuka wangiza.

Ikoreshwa cyane mu bikoresho bitandukanye byo gukora ibikoresho bya semiconductor: Amafuremu (icyuma gifata icyuma), Substrate (ishingiro), Arm/Bridge (manipulator), , Ibice bya Mechanical na Ceramic Air Bearing.

| Izina ry'igicuruzwa | Umuyoboro wa kera w’icyuma gishyushye cyane cya Alumina Ceramic 99 / Umuyoboro / Inkoni | |||||

| Urutonde | Ishami | 85% Al2O3 | 95% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | |

| Ubucucike | g/cm3 | 3.3 | 3.65 | 3.8 | 3.9 | |

| Kunywa Amazi | % | <0.1 | <0.1 | 0 | 0 | |

| Ubushyuhe bwa Sintered | ℃ | 1620 | 1650 | 1800 | 1800 | |

| Ubukomere | Mohs | 7 | 9 | 9 | 9 | |

| Ingufu zo Kugonda (20℃)) | Mpa | 200 | 300 | 340 | 360 | |

| Imbaraga zo Gukanda | Kgf/cm2 | 10000 | 25000 | 30000 | 30000 | |

| Ubushyuhe bw'igihe kirekire bwo gukora | ℃ | 1350 | 1400 | 1600 | 1650 | |

| Ubushyuhe ntarengwa bwo gukora | ℃ | 1450 | 1600 | 1800 | 1800 | |

| Ubushobozi bwo kwirinda ingano y'amazi | Ubushyuhe bwa 20°C | Ω. cm3 | >1013 | >1013 | >1013 | >1013 |

| 100℃ | 1012-1013 | 1012-1013 | 1012-1013 | 1012-1013 | ||

| 300℃ | >109 | >1010 | >1012 | >1012 | ||

Gukoresha ibumba rya alumina rifite isuku nyinshi:

1. Ikoreshwa ku bikoresho bya semiconductor: ceramic vacuum chuck, scatter disque, cleaner disque, ceramic CHUCK.

2. Ibice byo kohereza wafer: uduce dufata wafer, disiki zo gukata wafer, disiki zo gusukura wafer, ibikombe byo gusukura wafer optique.

3. Inganda zigaragaza urumuri rwa LED / LCD: umunwa w'urumuri rwa keramike, disiki yo gusya keramike, LIFT PIN, umuyoboro wa PIN.

4. Itumanaho ry'amajwi, inganda zikoresha imirasire y'izuba: imiyoboro ya ceramic, inkoni za ceramic, imashini zicapa ibyuma bya ceramic ku rubuga rwa interineti.

5. Ibice bikingira ubushyuhe kandi bikingira amashanyarazi: ibyuma bikingira amashanyarazi.

Kuri ubu, keramike ya aluminiyumu ishobora kugabanywamo ibice bibiri: ubuziranenge bwinshi n'ubusanzwe. Uruhererekane rw'amakaramike ya aluminiyumu ya okiside ifite ubuziranenge bwinshi ruvuga ibikoresho bya keramike birimo Al₂O₃ irenga 99.9%. Kubera ubushyuhe bwayo bugera kuri 1650 - 1990°C n'uburebure bwayo bwa 1 ~ 6μm, ikunze gutunganywa mu kirahuri givanze aho kuba platine crucible: ishobora gukoreshwa nk'umuyoboro wa sodium bitewe n'uko itanga urumuri kandi irwanya ingese ku byuma bya alkali. Mu nganda z'ikoranabuhanga, ishobora gukoreshwa nk'ibikoresho bikingira ubushyuhe bwinshi ku bikoresho bya IC. Dukurikije ibikubiye muri okiside ya aluminiyumu, uruhererekane rw'amakaramike ya aluminiyumu ya okiside isanzwe rushobora kugabanywamo keramike 99, keramike 95, keramike 90 na keramike 85. Hari igihe keramike ifite 80% cyangwa 75% bya okiside ya aluminiyumu nayo ishyirwa mu cyiciro cya keramike ya aluminiyumu ya okiside isanzwe. Muri byo, ibikoresho 99 bya aluminium oxide ceramic bikoreshwa mu gukora umuyoboro w'itanura ushyushye cyane, urinda umuriro n'ibikoresho byihariye bidashira, nk'amabati ya ceramic, imitako ya ceramic n'amabati ya valve. 95 bya aluminium ceramic bikoreshwa cyane cyane nk'igice kidashira kirwanya ingese. 85 bya ceramic bikunze kuvangwa mu miterere imwe n'imwe, bityo bikanoza imikorere y'amashanyarazi n'imbaraga za mekanike. Bishobora gukoresha molybdenum, niobium, tantalum n'izindi mitako z'icyuma, kandi bimwe bikoreshwa nk'ibikoresho by'amashanyarazi bivamo umwuka.

| Igicuruzwa cy'ubwiza (Agaciro k'ubuhagarariye) | Izina ry'igicuruzwa | AES-12 | AES-11 | AES-11C | AES-11F | AES-22S | AES-23 | AL-31-03 | |

| Ibigize imiti igabanya umunyu muke kandi byoroshye gukamura | H₂O | % | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| LOl | % | 0.1 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |

| Fe₂0₃ | % | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | 0.01 | |

| SiO₂ | % | 0.03 | 0.03 | 0.03 | 0.03 | 0.02 | 0.04 | 0.04 | |

| Na₂O | % | 0.04 | 0.04 | 0.04 | 0.04 | 0.02 | 0.04 | 0.03 | |

| MgO* | % | - | 0.11 | 0.05 | 0.05 | - | - | - | |

| Al₂0₃ | % | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | 99.9 | |

| Umwanya w'uduce duto (MT-3300, uburyo bwo gusesengura hakoreshejwe laser) | μm | 0.44 | 0.43 | 0.39 | 0.47 | 1.1 | 2.2 | 3 | |

| Ingano ya Crystal α | μm | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 ~ 1.0 | 0.3 ~ 4 | 0.3 ~ 4 | |

| Ubucucike bw'ingirabuzimafatizo** | g/cm³ | 2.22 | 2.22 | 2.2 | 2.17 | 2.35 | 2.57 | 2.56 | |

| Ubucucike bw'ibinure** | g/cm³ | 3.88 | 3.93 | 3.94 | 3.93 | 3.88 | 3.77 | 3.22 | |

| Igipimo cyo kugabanuka k'umurongo wo gusimbuza** | % | 17 | 17 | 18 | 18 | 15 | 12 | 7 | |

* MgO ntabwo iri mu ibarwa ry'ubuziranenge bwa Al₂O₃.

* Nta fu yo gupima 29.4MPa (300kg/cm²), ubushyuhe bwo gutwika ni 1600°C.

AES-11 / 11C / 11F: Ongeraho 0.05 ~ 0.1% MgO, ubushobozi bwo gusinya ni bwiza cyane, bityo ikoreshwa ku byuma bya aluminiyumu oxide bifite ubuziranenge burenze 99%.

AES-22S: Irangwa no kuba ifite ubucucike bwinshi n'umuvuduko muto wo kugabanuka k'umurongo ucukura, ikoreshwa mu gukata imiterere y'icyuma n'ibindi bicuruzwa binini bifite imiterere ikenewe.

AES-23 / AES-31-03: Ifite ubucucike bwinshi, thixotropy kandi ifite ubukana buke ugereranyije na AES-22S. Iya mbere ikoreshwa mu byuma bya ceramic mu gihe iya nyuma ikoreshwa mu kugabanya amazi mu bikoresho birinda umuriro, bigakundwa cyane.

♦Ibiranga Silicon Carbide (SiC)

| Ibiranga rusange | Ubuziranenge bw'ibice by'ingenzi (wt%) | 97 | |

| Ibara | Umukara | ||

| Ubucucike (g/cm³) | 3.1 | ||

| Gufata amazi (%) | 0 | ||

| Ibiranga ikoranabuhanga | Imbaraga zo koroha (MPa) | 400 | |

| Modulus y'abana bato (GPa) | 400 | ||

| Ubukomere bwa Vickers (GPa) | 20 | ||

| Ibiranga ubushyuhe | Ubushyuhe ntarengwa bwo gukora (°C) | 1600 | |

| Igipimo cyo kwaguka k'ubushyuhe | RT~500°C | 3.9 | |

| (1/°C x 10-6) | RT~800°C | 4.3 | |

| Ubushobozi bwo gutwara ubushyuhe (W/m x K) | 130 110 | ||

| Ubudahangarwa bw'ubushyuhe ΔT (°C) | 300 | ||

| Ibiranga amashanyarazi | Ubushobozi bwo kwirinda ingano y'amazi | 25°C | 3 x 106 |

| 300°C | - | ||

| 500°C | - | ||

| 800°C | - | ||

| Dielectrical constant | 10GHz | - | |

| Igihombo cya Dielectric (x 10-4) | - | ||

| Ikibazo cy'ibibazo (x 104) | - | ||

| Voltage ya dielectric breakdown (KV/mm) | - | ||

♦Silicon Nitride Ceramic

| Ibikoresho | Ishami | Si₃N₄ |

| Uburyo bwo gutonyanga | - | Umuvuduko wa Gazi Urimo Gushyuha |

| Ubucucike | g/cm³ | 3.22 |

| Ibara | - | Ikijuju cyijimye |

| Igipimo cyo kwinjiza amazi | % | 0 |

| Modulus y'Abasore | Gpa | 290 |

| Ubukomere bwa Vickers | Gpa | 18 - 20 |

| Imbaraga zo Gukanda | Mpa | 2200 |

| Imbaraga zo kunama | Mpa | 650 |

| Ubushobozi bwo gutwara ubushyuhe | W/mK | 25 |

| Ubudahangarwa bw'ihungabana ry'ubushyuhe | Δ (°C) | 450 - 650 |

| Ubushyuhe ntarengwa bwo gukora | °C | 1200 |

| Ubushobozi bwo kwirinda ingano y'amazi | Ω·cm | > 10 ^ 14 |

| Dielectric Constant | - | 8.2 |

| Imbaraga za Dielectric | kV/mm | 16 |