Mu gushaka utuntu duto, twihuta kandi dufite imbaraga nyinshi, ibyo abantu bakenera mu gutunganya ibikoresho bya Wafer birimo kwiyongera kugeza ku rwego rwo gukora neza mbere byafatwaga nk'ibidashoboka. Uko ibintu bigabanuka mu rwego rwa nanometero imwe, ni ko urubuga rwose rw'inganda rugenda rurushaho gukomera. Aha niho, munsi y'urusobe rw'ama-laser, ibyumba byo gusohoramo imashini, na sisitemu za roboti, ibikoresho bya kera—granite karemano—bigaragara nk'ikintu cy'ingenzi kugira ngo habeho intsinzi muri iki gihe. Ibisobanuro, ubuhanga, n'itangwa ry'ibice bya granite bya OEM bifite ubuhanga buhanitse hamwe n'icyuma cya granite cya OEM gifite imashini si ibya tekiniki gusa; ni byo shingiro ry'ubuziranenge bw'imikorere.

Uruhare rw'imashini muri sisitemu iyo ari yo yose ikora neza cyane ni ugutanga urwego rw'ifatizo rudahinduka kandi ruhamye. Mu gihe cyo gukora semiconductor mu buryo buhindagurika kandi bunoze, aho ibikorwa nka lithography, etching, no gushyiramo ibintu, ibintu bito bihindagurika—ndetse no ku rwego rwa sub-micron—bishobora gutera igihombo gikomeye. Guhitamo ibikoresho by'ibanze mu miterere, nk'imashini ikora Wafer Processing Equipment, ni intambwe idasubirwaho mu gushushanya.

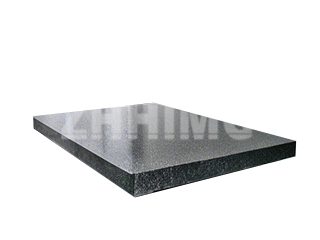

Ibyiza by'umwimerere bya Granite karemano

Kuki granite isanzwe irusha ibikoresho byakozwe mu buryo bwa ikoranabuhanga nk'icyuma gishongeshejwe, icyuma, cyangwa se bimwe na bimwe muri ubu buryo bwihariye? Igisubizo kiri mu miterere yayo yihariye kandi ishaje ikwiriye neza ibidukikije bitagereranywa by'imashini zikora neza.

1. Guhagarika ku buryo budasanzwe imitingito (Kwitandukanya n'Imikorere y'Ibintu):

Gutigita ni umwanzi w’inganda zikora ibintu bito cyane. Byaba bikorerwa imbere na moteri n’ibice byimuka cyangwa hanze bivuye mu cyumba cyo gusukura, gutigita kose kugomba kwinjizwa vuba. Granite ifite ubushobozi bwo kugabanya ubushyuhe bw’imbere mu buryo bworoshye—biruta cyane ibyuma. Iyi miterere bivuze ko ingufu za mekanike zihita zishira nk’ubushyuhe, bikarinda guhindagurika no kwemeza ko ibikorwa by’ingenzi bikorwa ku rubuga rudahinduka. Ibi ni ingenzi kugira ngo hagumane ahantu nyaho heza muri lithography igezweho cyangwa kugira ngo ibikoresho bivanweho kimwe mu gihe cyo gushyira ibintu mu buryo bwa chemical mechanical planarization (CMP).

2. Kwaguka kw'ubushyuhe hafi ya zeru (Gukomeza guhuza ubuziranenge):

Ibikoresho byo gutunganya Wafer bikunze kuba bikubiyemo ihindagurika ry'ubushyuhe, haba mu kirere cyangwa mu buryo buterwa n'imikorere. Ibikoresho by'icyuma birakura kandi bigatandukana cyane bitewe n'impinduka z'ubushyuhe, bigatuma ubushyuhe buhindagurika kandi bigatuma sisitemu z'amatara cyangwa mashini zihindagurika. Granite, cyane cyane granite y'umukara, igaragaza igipimo cyo kwaguka k'ubushyuhe (CTE) kiri hasi cyane, hafi 3 × 10⁻⁶/℃. Uku guhagarara k'ubushyuhe gutuma imiterere y'icyuma cya granite n'ibindi bice bya granite bya OEM bigumaho, bigabanya amakosa y'ubushyuhe kandi bikanatanga icyizere cyo gusubiramo ibipimo mu bihe bitandukanye.

3. Ubugari n'ubudahangarwa by'ikirenga:

Binyuze mu buryo bugezweho bwo gusimbuza no gusiga irangi, granite karemano ishobora kugera ku bugari bw'ubuso bupimirwa muri sub-microns—ikintu cy'ingenzi ku buso bw'ifatizo bukoreshwa mu kugenzura neza ingendo. Byongeye kandi, modulus yayo ya Young's ifite ubushobozi bwo gukomera no kudahinduka. Uku kudahinduka kw'uburibwe mu gihe cy'umutwaro ni ingenzi cyane, kuko ishingiro rigomba gushyigikira moteri nini, ibyiciro, n'inyubako zikomeye zo guteranya ibikoresho bya Wafer Processing Equipment zidafite impinduka ifatika, ndetse no mu gihe kinini.

Guhanga ahazaza: Ibice bya OEM Granite n'Inteko Ikomeye

Ikoreshwa rya granite rigezweho ntirigarukira ku masahani yoroshye yo hejuru. Inganda zikora ikoranabuhanga rigezweho muri iki gihe zisaba ibice bikomeye kandi byakozwe na OEM granite. Ibi bishobora kuba birimo imiyoboro y’umwuka iyobora, utumashini duto two mu bwoko bwa vacuum, ibikoresho byinshi byo gushyiramo ibyuma, hamwe n’ibikoresho byo gushyiramo imirasire ya laser na optique. Ibi bice akenshi bikoreshwa mu buryo bugoye, harimo imyobo icukuwe yo gukoresha insinga, ibikoresho byo gushyiramo imigozi, hamwe n’imirongo cyangwa imiyoboro ikozwe neza yo gushyiramo imiyoboro.

Uburyo bwo gukora iteranya ryuzuye ry’ibikoresho byo gutunganya Wafer ritangirana n’icyuma kinini cya granite. Ibice bya granite bikurikiraho bifatwa neza cyangwa bigahambirwaho hakoreshejwe ibintu bigezweho bishingiye kuri epoxy, intambwe y'ingenzi ituma imiterere yose ikora nk'ikintu kimwe kandi gihuye. Guhuza neza bisaba kwitabwaho cyane ku tuntu duto:

-

Guhindura: Ibice bigomba gukorwa hakurikijwe imiterere yihariye y'umukiriya, akenshi harimo no guhuza ibintu bitari granite nk'imirongo ikonjesha n'ibikoresho byo gushyiramo sensor mu buryo butaziguye.

-

Igenzura ry’Ubuziranenge: Buri gice gisaba kugenzura ubuziranenge mu buryo buhamye, harimo ubugari, ubw’ubuziranenge, no kugenzura ubugari hakoreshejwe CMM na laser interferometers, kugira ngo bigenzure neza ko byujuje ibisabwa na ISO n’amahame mpuzamahanga agenga ubuziranenge n’ubuziranenge.

-

Ubufatanye mu gutanga ibikoresho: Guhitamo umutanga ibikoresho bya granite wa OEM ni ubufatanye. Bisaba gusobanukirwa byimbitse ikoreshwa rya semiconductor, ubushobozi bwo guhitamo ibuye rito cyane, n'ubushobozi bwo gukora imashini no guteranya inyubako zigoye hakurikijwe ubushobozi bwa nanometer.

Mu gusoza, nubwo microchip irangiye ari igitangaza cy'ubuhanga bwa muntu, ikorwa ryayo rishingiye ku ituze rituje ritangwa n'amabuye karemano. Gukoresha granite mu buryo bugezweho nk'igikoresho cy'ingenzi cyo gukoresha imashini ya granite n'ibindi bice byihariye bya granite bya OEM ni ikintu cy'ingenzi mu gusunika imbibi za miniaturization. Ku bakora ibikoresho byo gutunganya Wafer, gukorana n'inzobere mu nyubako za granite zigezweho ni intambwe ya mbere kandi y'ingenzi yo kubona amahirwe yo guhangana ku isoko ry'ibikoresho bya semiconductor ku isi.

Igihe cyo kohereza: Ukuboza-01-2025