Ese?

Mu rwego rwo gukora ibikoresho bya semiconductor, ubuhanga bw'ibikoresho byo kugenzura wafer bugena neza ubwiza n'umusaruro wa chips. Nk'urufatiro rushyigikira ibice by'ingenzi byo gupima, ubuziranenge bw'ibikoresho by'ibanze bigira uruhare runini mu mikorere y'igihe kirekire y'ibikoresho. Granite n'icyuma gishongeshejwe ni ibikoresho bibiri bikunze gukoreshwa mu bikoresho byo kugenzura wafer. Ubushakashatsi bw'imyaka 10 bwagaragaje itandukaniro rikomeye hagati yabyo mu bijyanye no kudahindagurika kw'ibipimo, butanga ingero z'ingenzi zo guhitamo ibikoresho.

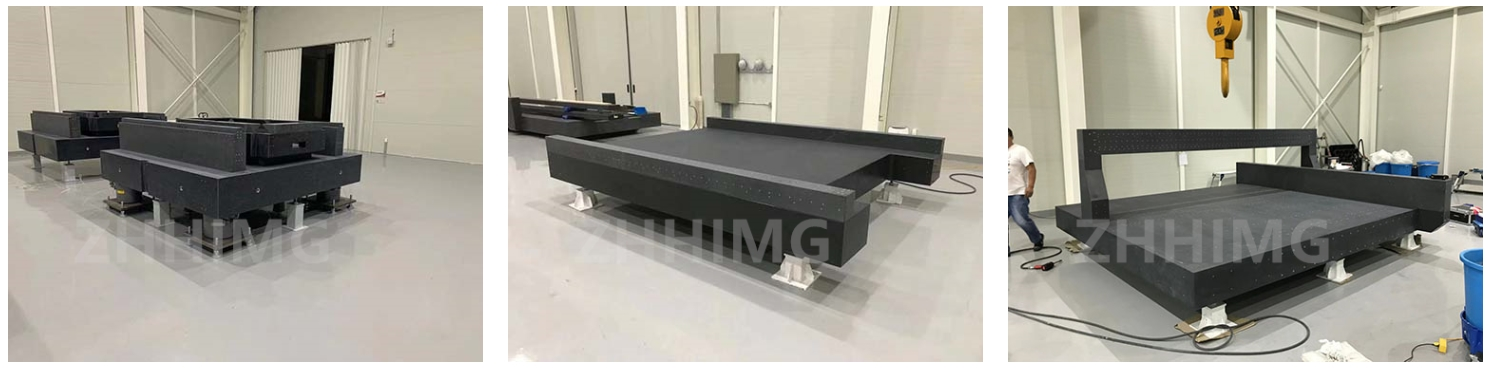

Ishusho n'igishushanyo mbonera by'igerageza

Uburyo bwo gukora wafer za semiconductor bufite ibisabwa byinshi cyane kugira ngo hamenyekane neza. Ndetse no kunyura mu rugero rwa mikorometero bishobora gutuma imikorere ya chip igabanuka cyangwa igasenyuka. Kugira ngo basuzume uburyo granite n'icyuma bihagaze neza mu gihe cy'igihe kirekire, itsinda ry'ubushakashatsi ryakoze igerageza ryigana imiterere nyayo y'aho bakorera. Ingero za granite n'icyuma bihagaze neza byatoranijwe bishyirwa mu cyumba cy'ibidukikije aho ubushyuhe bwahindukaga kuva kuri 15℃ kugeza kuri 35℃ naho ubushuhe bugahinduka kuva kuri 30% kugeza kuri 70% RH. Gutembera kwa mashini mu gihe cy'ikoreshwa ry'ibikoresho byakozwe hifashishijwe ameza yo gutembera. Ingano z'ingenzi z'ingero zapimwe buri gihembwe hakoreshejwe interferometer ya laser ifite ubuhanga bwo hejuru, kandi amakuru yakomezaga gufatwa mu gihe cy'imyaka 10.

Ibisubizo by'igerageza: Akamaro ntagereranywa k'amabuye ya granite

Imyaka icumi y'ubushakashatsi igaragaza ko icyuma cya granite kigaragaza ubudahangarwa butangaje. Igipimo cyacyo cyo kwaguka k'ubushyuhe kiri hasi cyane, kigera kuri 4.6 × 10⁻⁶ / ℃ gusa. Mu gihe cy'impinduka zikomeye z'ubushyuhe, ihindagurika ry'ibipimo rihora rigenzurwa muri ± 0.001mm. Mu gihe cy'impinduka z'ubushuhe, imiterere y'ubucucike bwa granite ituma idahinduka, kandi nta mpinduka zipimye zibaho. Mu gihe cy'impinduka za mekanike, imiterere myiza y'impinduka za granite ifata neza ingufu z'impinduka, kandi ihindagurika ry'ibipimo ni rito cyane.

Mu buryo bunyuranye, kuri substrate y'icyuma gishongeshejwe, impuzandengo y'ubushyuhe bwayo igera kuri 11 × 10⁻⁶/℃ - 13 × 10⁻⁶/℃, kandi ihinduka ry'ubushyuhe riterwa n'impinduka z'ubushyuhe mu myaka 10 ni ± 0.05mm. Mu hantu hashyushye, icyuma gishongeshejwe gishobora kwangirika no kwangirika. Ingero zimwe na zimwe zigaragaza impinduka zo mu gace, kandi ihinduka ry'ubushyuhe rirushaho kwiyongera. Mu gihe cy'ihindagurika ry'icyuma, icyuma gishongeshejwe gifite ubushobozi buke bwo kudakoresha ihindagurika ry'ubushyuhe kandi ingano yacyo irahindagurika kenshi, bigatuma bigorana kuzuza ibisabwa mu buryo bunonosoye bwo kugenzura wafer.

Impamvu y'ingenzi y'itandukaniro mu ituze

Granite yashinzwe mu myaka amagana na miriyoni binyuze mu miterere y’ubutaka. Imiterere yayo y’imbere ni minini kandi ingana, kandi kristu z’amabuye y’agaciro ziteguye neza, zikuraho imihangayiko y’imbere mu buryo busanzwe. Ibi bituma idahangayika cyane n’impinduka mu bintu byo hanze nko mu bushyuhe, ubushuhe n’ihindagurika ry’ikirere. Ibyuma bikozwe mu buryo bwo gucukura kandi bifite inenge ntoya nk’imyenge n’imyobo y’umucanga imbere. Hagati aho, imihangayiko isigaye iterwa no gucukura ishobora guteza impinduka mu ngero bitewe no gukangura ibidukikije byo hanze. Imiterere y’icyuma cy’icyuma gituma gishobora kugwa bitewe n’ubushuhe, kikihutisha kwangirika kw’imiterere no kugabanya ubuziranenge bw’imiterere.

Ingaruka ku bikoresho byo kugenzura wafer

Ibikoresho byo kugenzura imashini hakoreshejwe granite, hamwe n’imikorere yayo ihamye, bishobora kwemeza ko sisitemu yo kugenzura igumana ubuziranenge bwo hejuru igihe kirekire, bigabanye isuzuma ritari ryo no kutabona neza bitewe no guhindagurika kw’ibikoresho, kandi bikanoza cyane umusaruro w’ibicuruzwa. Hagati aho, ibisabwa bike byo kubungabunga bigabanya ikiguzi cy’ubuzima bwose bw’ibikoresho. Ibikoresho bikoresha substrates z’icyuma gishongeshejwe, bitewe no kudakomera neza kw’ibipimo, bisaba gupima no kubungabunga kenshi. Ibi ntibyongera gusa ikiguzi cyo gukora ahubwo bishobora no kugira ingaruka ku bwiza bw’umusaruro wa semiconductor bitewe no kudakora neza bihagije, bigatera igihombo mu bukungu.

Dukurikije uko inganda za semiconductor zishaka gukoresha ikoranabuhanga rigezweho kandi rifite ubuziranenge buhanitse, guhitamo granite nk'igikoresho cy'ibanze cyo gukoresha mu gupima ibikoresho bya wafer nta gushidikanya ko ari igikorwa cyiza cyo kwemeza ko ibikoresho bikora neza kandi kongerera imbaraga amasosiyete.

Igihe cyo kohereza: Gicurasi-14-2025