?

Mu nganda zikoresha ibikoresho bya CNC, kugenzura neza, gutuza no kuramba nibyo bipimo byingenzi byo gupima imikorere yibikoresho. Granite, hamwe nibintu byihariye byumubiri nubumara, byahindutse buhoro buhoro ibikoresho byingenzi mugukora ibikoresho bya CNC kandi bikoreshwa cyane mubikoresho bitandukanye byingenzi, bitera imbaraga nshya mugutezimbere inganda. ?

I. Gukoresha Scenarios ya Granite muri CNC Ibikoresho Byigenzura

Urwego rwibanze rwimashini

Mubice nkibikorwa bitunganijwe neza hamwe nibice byindege bikora, ibisabwa cyane birashyirwa kumurongo wukuri kandi ugasubiramo neza aho ibigo bikora. Granite, hamwe nibyiza byayo, ikoreshwa nkibikoresho fatizo byo murwego rwohejuru rwimashini. Imiterere yubucucike hamwe nuburemere bukomeye birashobora gushyigikira neza ibice byingenzi bigize igikoresho cyimashini nka spindle hamwe nuyobora inzira, kugabanya amakosa yo gutunganya yatewe no guhindura imikorere. Kurugero, mugihe utunganya ibishushanyo bya moteri ya aero hamwe nuburinganire bugoramye, ikigo gikora imashini ukoresheje granite base gishobora kwemeza neza inzira yinzira kandi kigateza imbere imiterere yibibumbano. ?

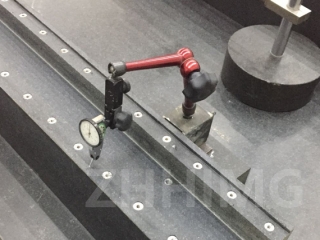

2. Guhuza imashini eshatu zipima imashini

Imashini yo gupima imirongo itatu ni ibikoresho byingenzi byo kugenzura ubuziranenge mu gutunganya CNC, kandi ibipimo byayo bipima bigira ingaruka ku bwiza bw’ibicuruzwa. Ibikoresho bya Granite, hamwe nuburinganire bwabyo buhebuje (kugeza kuri 0.1μm / m) hamwe nubutaka buke cyane (Ra≤0.02μm), bitanga ubuso buhamye bwo gupima iperereza. Iyo ugenzuye ibipimo, imiterere hamwe no kwihanganira imyanya yibice byuzuye, urubuga rwa granite rushobora kwirinda neza amakosa yo gupimwa yatewe no guhinduka kwabo cyangwa ubuso butaringaniye, byemeza neza niba amakuru yubugenzuzi ari ukuri. ?

3. Kuyobora gari ya moshi kubikoresho bya mashini ya CNC

Imikorere ya gari ya moshi iyobora igena ubworoherane nukuri kwimashini yimashini igenda. Imiyoboro ya Granite iranga coefficient nkeya yo guterana no kwihanganira kwambara. Ugereranije nicyuma kiyobora ibyuma, birashobora kugabanya kwambara ibice byimuka no kugabanya inshuro zo kubungabunga. Hagati aho, imikorere yacyo nziza cyane irashobora gukurura neza kunyeganyega mugihe cyo gukora igikoresho cyimashini no kuzamura ubwiza bwubuso bwakorewe. Muburyo bwihuse bwo gukata, inzira ya granite iyobora irashobora kugumisha igikoresho cyo gutema muburyo butajegajega, kugabanya ububobere bwubuso bwibikorwa, no kunoza imikorere no gutunganya ibicuruzwa. ?

4. Amashanyarazi asohora imashini ibikoresho byimashini ikora

Mugihe cyo gutunganya amashanyarazi asohora amashanyarazi, ubushyuhe bwo hejuru hamwe nimbogamizi ya electromagnetique biravuka, ibyo bikaba bisaba ibisabwa cyane kumutekano no kubika akazi. Granite ntabwo ifite gusa ubushyuhe buhebuje bwumuriro, bushobora guhangana nihindagurika ryubushyuhe mugihe cyo kuyitunganya, ariko kandi ifite imiterere yimiterere karemano kandi ntabwo iterwa no kwivanga kwa electronique. Kubwibyo, intebe yakazi ya granite irashobora gutanga ibidukikije bihamye byo gutunganya amashanyarazi, bigatuma gutunganya neza hamwe nubuziranenge bwubutaka. ?

Ii. Ibyiza bya Granite muri CNC Ibikoresho Byigenzura

Kugaragara neza

Mugihe cyigihe kirekire gikora cyibikoresho bya CNC, havuka ubushyuhe bwinshi, bigatuma ubushyuhe bwaguka no kugabanuka kwibikoresho. Coefficient yo kwagura ubushyuhe bwa granite iri hasi cyane (4-8 × 10⁻⁶ / ℃ gusa), kandi ubunini bwayo ntibuhinduka mugihe ubushyuhe bwahindutse, bushobora kwirinda neza amakosa yo gutunganya no gutandukana kubipimo biterwa no guhindura ubushyuhe. Kurugero, mubihe byubushyuhe bwo hejuru, ibikoresho bya CNC bifite base ya granite birashobora gukomeza kugumya gutunganya neza, kwemeza ko ibicuruzwa bitagira ingaruka kumihindagurikire yubushyuhe. ?

2. Imikorere myiza yo kurwanya vibrasiya

Mugihe cyo gutunganya CNC, imikorere yihuse yigikoresho cyimashini nimbaraga zo gukata bizatera kunyeganyega, bigira ingaruka kumashini neza hamwe nubuziranenge bwubuso. Imiterere yihariye ya kirisiti imbere muri granite iyiha imikorere myiza yo kugabanuka, ikabasha kwihutisha guhuza imbaraga zinyeganyeza zo hanze no kugabanya kwivanga kwinyeganyeza. Ubushakashatsi bwakozwe bwerekana ko igipimo cyo kugabanya granite gishobora kugera kuri 0.05-0.1, kikaba cyikubye inshuro 5-10 z'ibyuma. Irashobora kugabanya neza kunyeganyeza ibikoresho hamwe no guhindagurika kwakazi, kandi bigateza imbere gutunganya no kurangiza neza. ?

3. Gukomera cyane no kwambara birwanya

Granite ifite ubucucike buri hejuru (kugeza kuri 2,6-3.0g / cm³) no gukomera gukomeye (hamwe na Mohs ikomeye ya 6-7), kandi igaragaramo gukomera no kwambara birwanya. Iyo ikorewe imitwaro iremereye hamwe nubukanishi bwibikoresho bya CNC, ibice bya granite ntibishobora guhinduka cyangwa kwambara kandi birashobora kugumya guhagarara neza mugihe kirekire. Nk’uko imibare ibigaragaza, igihe cyo kubika neza ibikoresho bya CNC ukoresheje ibice bya granite birashobora kuba birebire inshuro 3 kugeza kuri 5 ugereranije n’ibikoresho gakondo by’icyuma, bikagabanya cyane amafaranga yo gufata neza ibikoresho n’igihe cyo gutaha. ?

4. Gukomera kwimiti

Mubikorwa byo gutunganya CNC, hakoreshwa imiti ya chimique nko gukata amazi n'amavuta, kandi ibyo bintu bishobora gutera kwangirika kubikoresho. Granite ifite imiti ihamye, igipimo kinini cyo kwihanganira pH (1-14), irashobora kurwanya isuri yibintu bisanzwe, kandi ntibishobora kwangirika cyangwa kwangirika. Iyi mikorere ntabwo yongerera igihe serivisi yumurimo wibikoresho gusa, ahubwo inashimangira isuku y’ibidukikije bitunganyirizwa, birinda ingaruka ku bwiza bw’ibicuruzwa bitewe n’umwanda w’imiti. ?

Kuruhande rwibikoresho bya CNC bigenzura ibikoresho byinganda bikomeje gukurikirana neza kandi neza, granite, hamwe nibyiza byayo nko guhagarika ubushyuhe, kurwanya ibinyeganyega, gukomera gukomeye hamwe n’imiti ihamye, bigira uruhare rudasubirwaho mubikoresho bitandukanye byingenzi. Hamwe niterambere ryiterambere ryikoranabuhanga, ibikoresho bya granite bizakoreshwa cyane murwego rwa CNC, biteze imbere inganda gutera imbere muburyo bunoze kandi bufite ireme..

Igihe cyo kohereza: Gicurasi-24-2025