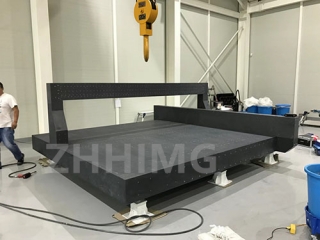

Mu ikorwa ry’ibikoresho bya semiconductor, ibisabwa mu ikorwa rya chips ku bijyanye n’ibidukikije n’uburyo ibikoresho bihagaze neza ni byinshi cyane, kandi kunyuranya guto bishobora gutuma umusaruro wa chips ugabanuka cyane. Urubuga rwa XYZT rukoresha uburyo bwo kugenda bwa gantry bukoresha granite kugira ngo rufatanye n’ibindi bice bya platforms kugira ngo hubakwe urufatiro rukomeye rwo kugera ku buryo nanoscale ikora neza.

Imiterere myiza yo gukumira gutigita

Mu icungamutungo rikora ibikoresho bya semiconductor, imikorere y'ibikoresho byo ku ruhande n'abakozi bagenda hirya no hino ishobora gutera gutigita. Imiterere y'imbere y'ibice bya granite ni minini kandi ingana, ifite imiterere isanzwe yo gutigita cyane, nk'"inzitizi" nziza yo gutigita. Iyo gutigita hanze byoherejwe kuri platform ya XYZT, igice cya granite gishobora kugabanya neza ingufu zirenga 80% by'ingufu zo gutigita no kugabanya ingaruka zo gutigita ku buryo buboneye bwo kugenda kwa platform. Muri icyo gihe, platform ifite sisitemu yo kuyobora umwuka neza cyane, ikorana n'ibice bya granite. Ubuyobozi bwo kuyobora umwuka bukoresha filime ya gaze ihamye ikorwa na gaze ifite umuvuduko mwinshi kugira ngo imenyereze ingendo zo guhagarika ibice byimuka bya platform kandi igabanye gutigita guto guterwa no gutigita kwa mashini. Bombi hamwe, bireba ko uburyo bwo gushyira platform neza buri gihe buguma ku rwego rwa nanometer mu bikorwa by'ingenzi nka chip lithography na etching, kandi birinda gutandukana kw'imiterere ya chip circuit iterwa no gutigita.

Ubushyuhe buhamye cyane

Ihindagurika ry'ubushyuhe n'ubushuhe mu iduka rikora ibikoresho bifite ingaruka zikomeye ku buryo ibikoresho bikora ibikoresho bipima ubushyuhe. Igipimo cyo kwaguka k'ubushyuhe bwa granite kiri hasi cyane, muri rusange kiri kuri 5-7 × 10⁻⁶/℃, ingano ntabwo ihinduka iyo ubushyuhe buhindutse. Nubwo itandukaniro ry'ubushyuhe hagati y'amanywa n'ijoro mu iduka cyangwa umusaruro w'ubushyuhe bw'ibikoresho rituma ubushyuhe bw'ikirere buhindagurika, ibice bya granite bishobora kuguma bihamye kugira ngo birinde guhinduka kw'urukuta bitewe no kwaguka no guhindagurika k'ubushyuhe. Muri icyo gihe, sisitemu y'ubushyuhe ifite ubwenge ifite urukuta ikurikirana ubushyuhe bw'ikirere mu gihe nyacyo, igahindura mu buryo bwikora ibikoresho bitanga umwuka n'ubushyuhe, kandi ikabungabunga ubushyuhe bw'iduka kuri 20 ° C ± 1 ° C. Hamwe n'ibyiza byo kudahinduka k'ubushyuhe bwa granite, igenzura ko urukuta rukora neza igihe kirekire, uburyo buri ruhande rukora neza buri gihe buhuye n'ibipimo ngenderwaho by'ubuziranenge bwa nanometer mu ikorwa rya chip, kugira ngo harebwe ko ingano y'ishusho ya chip lithography ari nziza, kandi ko uburebure bw'ubushyuhe bungana.

Haza ibyifuzo by'ibidukikije bisukuye

Inzu ikora ibikoresho bya semiconductor igomba kugira isuku yo ku rwego rwo hejuru kugira ngo hirindwe ko uduce tw'umukungugu twanduza chip. Granite ubwayo ntabwo itanga umukungugu, kandi ubuso bwayo buraryoshye, ntabwo byoroshye kuyikuramo umukungugu. Urubuga muri rusange rufata igishushanyo mbonera cy'imiterere gifunze neza cyangwa gifunze neza kugira ngo bigabanye kwinjira kw'umukungugu wo hanze. Sisitemu yo kuzenguruka k'umwuka imbere ihujwe na sisitemu yo gukonjesha umwuka isukuye yo mu iduka kugira ngo isuku y'umwuka imbere igere ku rwego rusabwa n'ikorwa rya chip. Muri iki gipimo gisukuye, ibice bya granite ntibizagira ingaruka ku mikorere iterwa n'isuri y'umukungugu, kandi ibice by'ingenzi nka sensors na moteri by'urubuga bishobora gukora neza, bitanga garanti ihoraho kandi yizewe yo gukora chips, kandi bigafasha inganda za semiconductor kugera ku rwego rwo hejuru rw'imikorere.

Igihe cyo kohereza: 14 Mata 2025